In several industries, the utilization of 3D prototype printing has demonstrated to be extremely beneficial. This new approach to manufacturing allows companies to generate a prototype of a product at a fraction of the fee and time it would normally take. The advantages of this process rely on the type of project, the complexity of the look and a it's used in.

Like, while 3D printing is not suitable for metals, those looking for a rapid and economical option to build a metal prototype can turn to investment casting, which has a similar timetable and doesn't include any extra expenses. Despite its drawbacks, additive manufacturing continues to be the preferred technology in many fields of expertise.

Additionally, 3d printing service is incredibly adaptable, in addition to being cost-effective. The many kinds of material that can be used for prototyping could be obtained within the internet. Materials such as for instance ABS, plastic, and polyamide, like, can be found at many different pricing points and have a wide variety of qualities to decide on from.

Even though that numerous businesses employ many different materials, they must select one that is most befitting their requirements. The materials used for prototypes should really be sturdy enough to endure the stresses of testing. Biocompatible materials must also be employed in the manufacture of food and medical items.

While 3D prototype printing is commonly used to generate functional models, investment casting is a preferable selection for large parts. For small parts, investment casting is a great choice. It may be used to produce moulds and sand casting patterns, among other things.

Even though that each circumstance is exclusive, investment casting provides great quantities of dependability and cost savings. At the end of the day, you should conduct a price analysis for each one of these possibilities to be able to determine that will be the best option for the firm. The decision will soon be based on the level of metal you require to be stated in the first place.

Following the choice of the material for the prototype, you are able to go on to the creation of your functional model, that is the final step. Which means that your prototype must be the same size and weight as your final product, in addition to execute the exact same functions as your final product. You'll also use this information to determine whether you need to proceed with mass production only at that stage.

Furthermore, it'll enable you to secure money for production, to licence your invention, or to promote your product successfully after it has launched. You have to, however, make sure you see most of these elements in order to determine which alternative is the most advantageous.

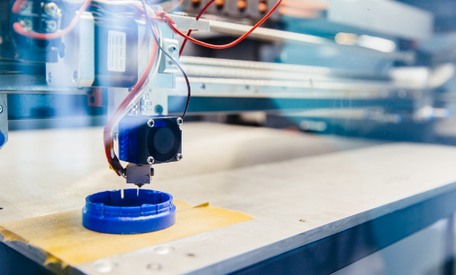

FDM is another 3D printing technique that makes use of plastic filament to extrude single layers onto a printing plate and soon you achieve the mandatory 3D design. For probably the most part, FDM is just a versatile approach that can be utilised to create both large-scale and low-volume goods. For example, you can make a prototype by printing off a 2D image of the product from some type of computer screen. Then you may utilize the same model to produce multiples of it using the same technique.

No comments:

Post a Comment