Vibration fixture design is a field of engineering that needs knowledge of numerous disciplines and complex calculations. It involves designing components and structures to aid, locate, and constrain objects against vibration in order to reduce or eliminate noise and movement that can cause damage or malfunction of the parts being tested. In this article, we will learn about the basic principles of vibration test lab.

What Is Vibration Fixture Design ?

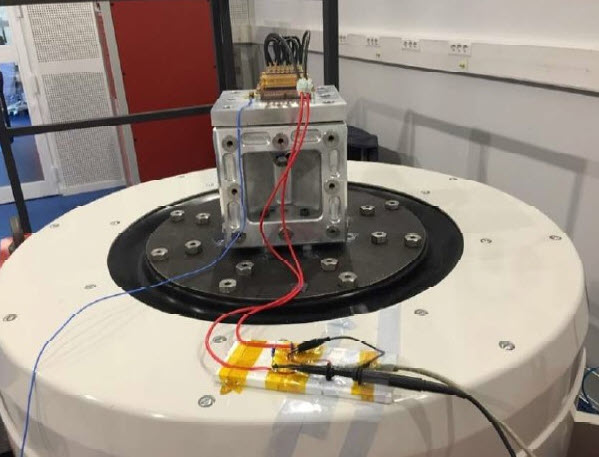

Vibration fixture design is the process of designing fixtures that can handle safely holding and testing objects under loads, vibrations, and other environmental conditions during product development or production processes. The target is to ensure that the thing being tested performs in accordance with specification without any threat of damage as a result of excessive movement or vibration.

When it comes to vibration fixture design , there are several factors that really must be taken under consideration including material selection, mounting location, load requirements, damping characteristics, stiffness requirements, geometric configuration and more. Every one of these elements have to be carefully analyzed for the fixture design to meet its desired function.

Design Considerations

When designing a vibration fixture for use in product development or production processes, several important factors must be studied into account. For example:

Material Selection: The kind of material utilized in the construction of the fixture should be selected centered on its capability to withstand various types of loading conditions as well as its durability over time. Different materials can also require different methods for mounting onto test equipment or machines.

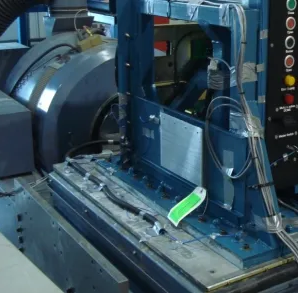

-Mounting Location: Where in actuality the vibrating element is mounted relative to other components within the system should really be carefully considered as it can certainly have an immediate influence on performance. The location should also take into consideration accessibility for maintenance purposes along with safety considerations when coping with high-speed vibrations that could potentially cause injury if not properly contained.

-Load Requirements: Every application has different load requirements which must also be taken under consideration when designing a vibration fixture. These generally include static loads such as for instance dead weights applied directly onto the vibrating element as well as dynamic loads such as for instance those resulting from motion caused by acceleration or deceleration over time.

-Damping Characteristics: Damping characteristics reference just how much energy is lost from a vibrating object because of friction between components within the device itself or between adjacent surfaces within the environmental surroundings where it resides (air for instance). It's important to think about damping characteristics when designing a vibration fixture since they directly affect simply how much energy is lost through friction during operation and thus just how much force must be applied by other components (e.g., actuators) for desired degrees of performance are achieved during testing procedures.

Vibration fixtures play an important role in product development and production processes by giving support against unwanted movement caused by external forces such as vibrations or changing environmental conditions like temperature fluctuations over time. By understanding these basics behind vibration fixture design—including material selection, mounting location considerations, load requirements analysis, damping characteristics assessment geometric configuration analysis—engineers can make sure that their designs are optimized for maximum performance while also accounting for safety concerns related too high-speed operations if necessary.

No comments:

Post a Comment